Ultrasonic Systems Built for Passivation-Ready Cleanliness

The passivation process only works if the stainless steel surface is truly clean. Oils, residues, and microscopic debris can prevent acids from properly contacting stainless steel, leading to issues such as inconsistent passivation, corrosion failures, and rejected parts.

TPS Products is here to help. Our industrial ultrasonic parts washers are engineered for deep, microscopic cleaning that supports reliable, repeatable passivation results, even on complex, high-precision components.

What Is Passivation?

Passivation is a chemical surface treatment applied to stainless steel. It removes debris and contaminants from the surface and enhances the metal’s natural corrosion resistance.

The passivation process involves:

Step 1: Cleaning. Oils, coolants, polishing compounds, and shop dirt must be removed.

Step 2: Acid treatment. Parts are immersed in a nitric acid or citric acid bath to dissolve contaminants

Step 3: Oxide layer formation. Exposure to air or water allows a uniform chromium oxide layer to form

Step 4: Rinse & dry. The process leaves a clean, corrosion-resistant surface

The Problem: Traditional Cleaning Isn’t Enough

Conventional spray washers, soak tanks, and manual cleaning methods often fail to remove things like embedded machining oils, trapped residue, and fine particulates. When those contaminants remain, passivation baths can’t do their job.

That leads to:

Uneven oxide layers

Reduced corrosion resistance

Costly rework or scrap

The Solution: Ultrasonic Parts Washers That Prepare Metal at the Microscopic Level

Image courtesy of TierraTech

Our multi-stage ultrasonic cleaning systems use high-frequency sound waves to create millions of cavitation bubbles that implode against the part surface. Ultrasonic parts washers help you reach areas no spray or brush can touch and remove unwanted contaminants at a microscopic level. As a result, you get uniform cleanliness across every part

Ultrasonic cleaning is widely considered the gold standard for pre-passivation cleaning. TPS Products is proud to offer high-quality, durable ultrasonic parts washers from TierraTech, one of the leading manufacturers in the industry.

Our TierraTech ultrasonic parts washers are a game-changer for the critical pre-passivation cleaning step in high-spec manufacturing environments. They allow you to:

Reach difficult spots, like blind holes, threads, and internal channels

Remove machining oils, polishing compounds, and embedded residues

Deliver uniform surface cleanliness across complex geometries

Prepare stainless steel for consistent, effective passivation

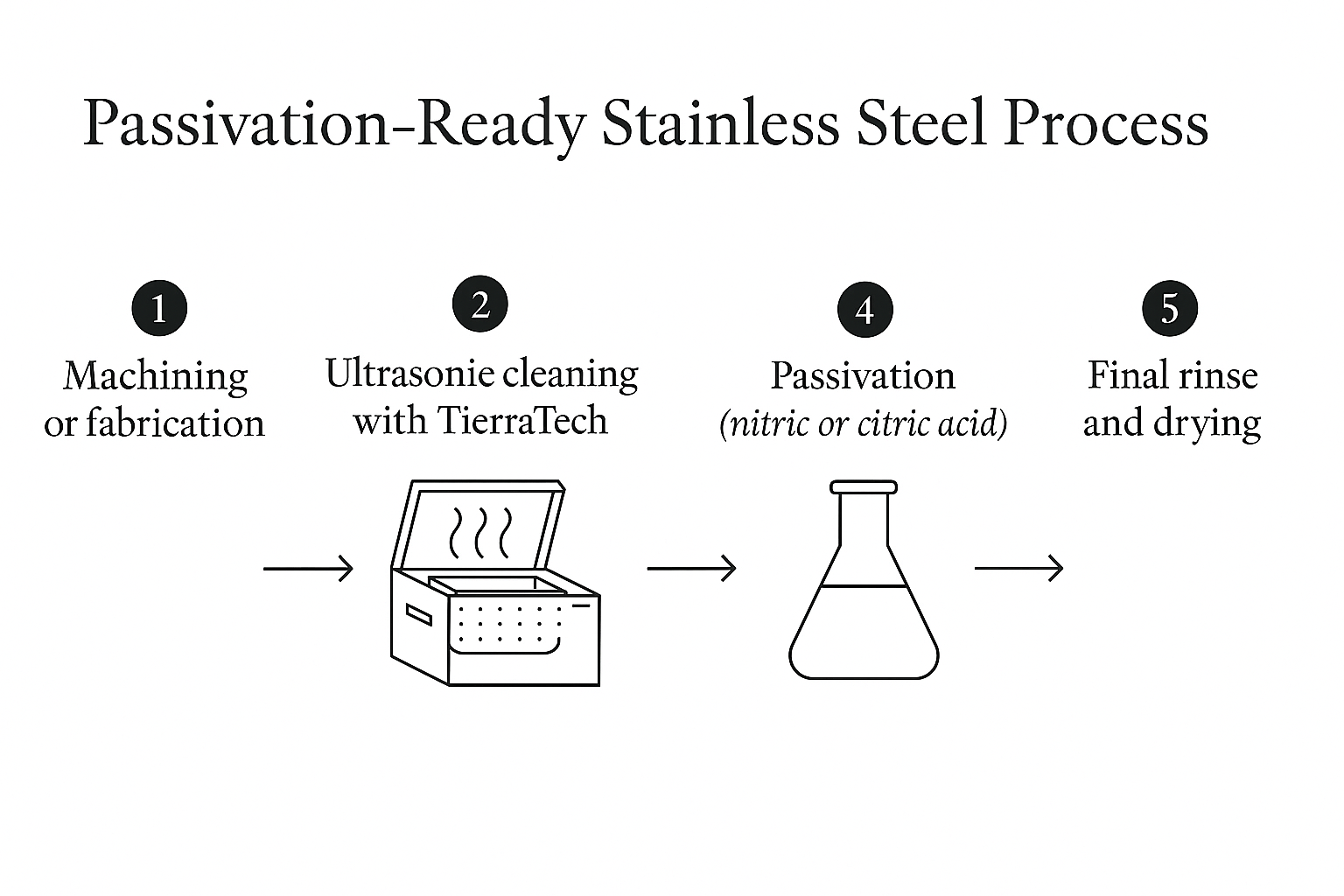

A Proven Passivation-Ready Workflow

By using TierraTech ultrasonic cleaning as the foundation of your process, you can improve passivation consistency, reduce corrosion-related failures, and protect downstream quality and compliance

Machining or fabrication

Ultrasonic cleaning with TierraTech

Rinse

Passivation (nitric or citric acid)

Final rinse and drying

Designed for Passivation-Critical Industries

TierraTech ultrasonic parts washers are trusted by manufacturers where surface integrity and corrosion resistance are non-negotiable.

-

In aerospace and defense applications, ultrasonic parts washing systems prepare precision-machined stainless steel components for passivation by thoroughly cleaning tight-tolerance parts and complex geometries. By enabling uniform surface preparation, TierraTech washers support ASTM A967 and A380 passivation workflows while reducing the risk of corrosion-related failures.

-

Manufacturers of food and beverage equipment use ultrasonic parts washers to prepare sanitary stainless steel parts and assemblies for hygienic passivation. Deep ultrasonic cleaning removes residues that can compromise corrosion resistance, helping ensure clean, passivation-ready surfaces that meet sanitation expectations.

-

Ultrasonic parts washers are widely used in manufacturing, particularly semiconductor and electronics to clean ultra-sensitive stainless steel process hardware. The ability to remove microscopic contaminants from internal passages and complex features makes ultrasonic cleaning essential for high-purity applications where residue impacts performance.

-

Precision CNC and contract manufacturers use TierraTech ultrasonic cleaning systems to clean stainless steel parts headed directly to passivation. By delivering consistent, microscopic-level cleanliness, you reduce rework, minimize downstream passivation failures, and improve first-pass yield across a wide range of part geometries and production volumes.

Why Our Ultrasonic Washers Are Different

TierraTech doesn’t build generic ultrasonic tanks — and that’s why we work with them. These process-critical ultrasonic cleaning systems are designed to perform in demanding industrial environments.

Engineered for Passivation-Ready Results

Optimized ultrasonic frequencies for stainless steel

Uniform cavitation across the tank

Compatible with alkaline and neutral detergents

Easy integration into ASTM-compliant workflows

Designed for Complex Parts

Cleans threads, blind holes, slots, and internal channels

Ideal for parts that spray washers can’t handle

Consistent cleaning batch after batch

Scalable to Your Operation

Benchtop to large-format systems

Manual, semi-automated, or automated lines

Optional heated tanks and multi-stage configurations

take your passivation process to the next level

If your stainless steel parts require passivation, ultrasonic cleaning is not optional—it’s essential.

With TierraTech ultrasonic parts washers, TPS Products help manufacturers achieve the level of cleanliness passivation demands, protecting product performance, quality, and reputation.

Ready to get started?